|  |

phone: +7 495 1087345 fax: +7 495 1087345 office@trans-service.org |

Diesel Diagnosis Systems (DDS)

Overview:

Monitoring System Hardware:

System Use:

Back to "Diesel Diagnosis Systems (DDS)"

Monitoring Modes

1. Engine Protection (Background) Mode

2. Main Engine Mode

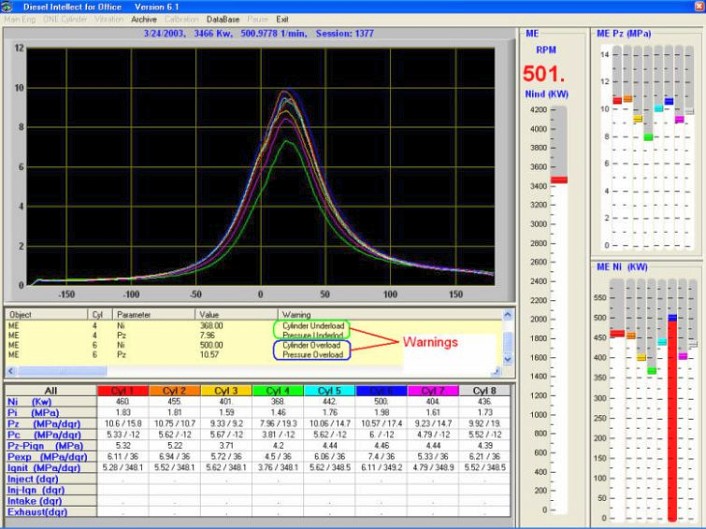

Figure 6.1

3. One Cylinder Mode

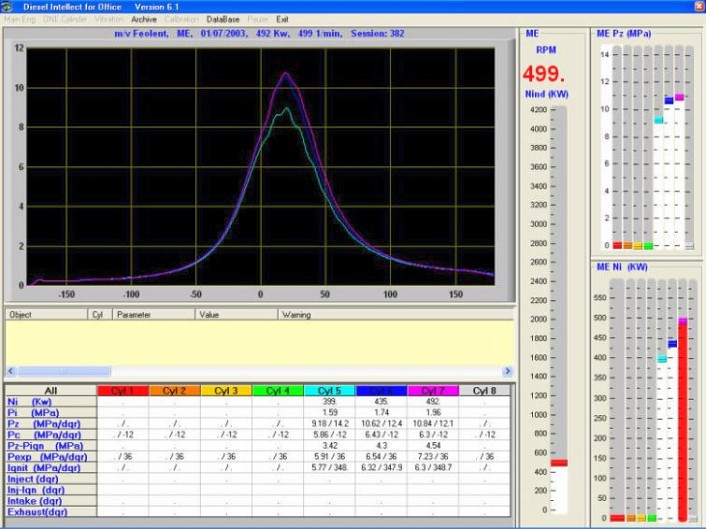

Figure 6.2

4. Vibration

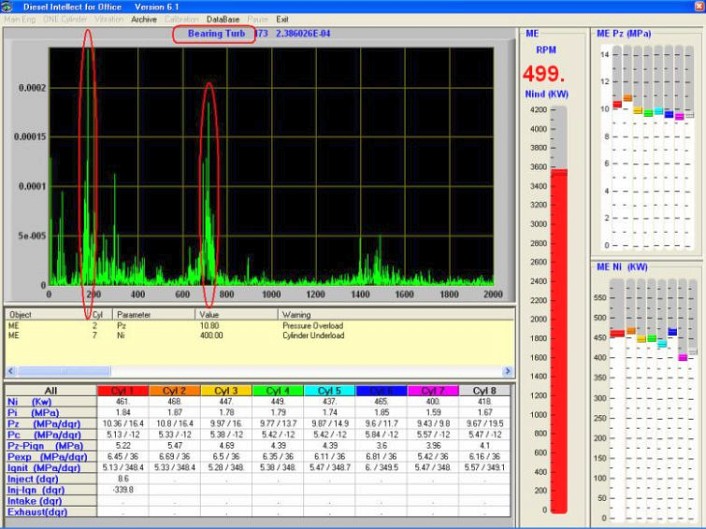

Figure 6.3

5. Archive Mode

6. Track Mode

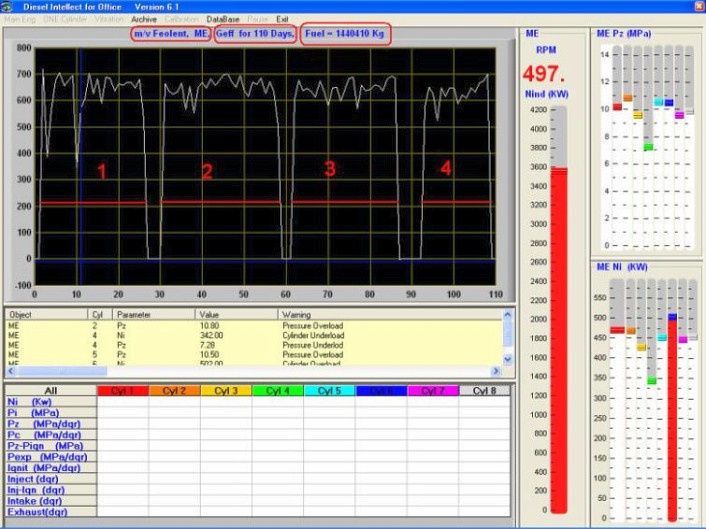

Figure 6.4

7. Calibration

8. Database

General Information: