|  |

phone: +7 495 1087345 fax: +7 495 1087345 office@trans-service.org |

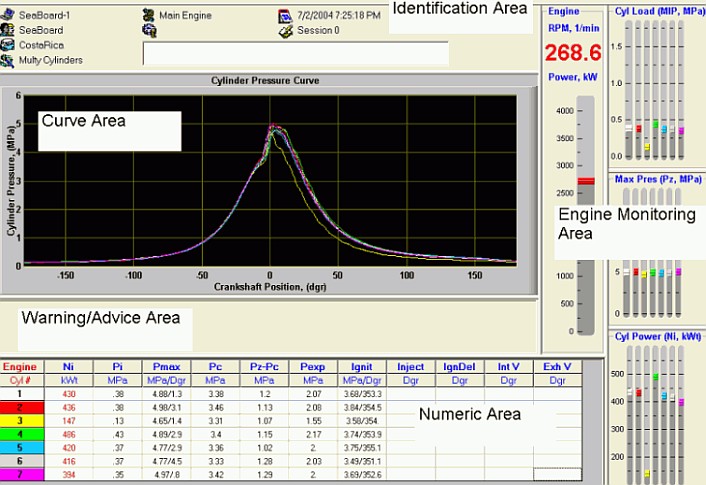

Diesel Diagnosis Systems (DDS)

Our company’s specialists arrange delivery and installation of the unique diesel diagnosis systems

The system is supplied:

DII’s Combustion Engine Monitoring System (DII-7) has been developed to monitor reciprocating engine performance parameters by means of electronic sensors installed in the cylinders. The portable version is designed for short-term, temporary use, such as periodic testing and adjustment. The permanent complex is used for continuous monitoring of combustion process inside every cylinder. Using the system helps to spot engine malfunctions at an early stage, yielding benefits in proper preventive maintenance scheduling, emergency avoidance and engine overload protection. As per client’s request the permanent complexes may be additionally equipped with the main and crankpin bearings’ temperature sensors, exhaust gases temperature and other sensors. The system may also be coordinated with the main engine control system for control of revolutions or emergency stop upon detection of critical parameter.

Main features:

Based on the monitoring data the DII-7 will issue immediate Advice for improved engine loading and tuning.

General Information: